Deaerator/Deaerating Tank Manufacturers & Suppliers India, Maharashtra

We are leading Deaerators and Deaerating Tanks manufacturers, suppliers, and exporters in India, specifically located in Maharashtra. With years of experience in the industry, we pride ourselves on providing high-quality solutions that meet the needs of various sectors, including power generation, process industries, and more. Our dedication to innovation and excellence has made us a trusted name in the field.

Like all other fluids used as heat transfer mediums, water includes non-condensable gases like oxygen. These dissolved gases act as an insulator against heat transfer in a fluid. When these gases are present in a fluid, heat transfer rates from fuel to fluid are typically reduced. This affects efficiency by raising the amount of fuel needed for heating.

Working of Deaerator Tank

A Deaerator is a crucial piece of equipment used to eliminate dissolved gases, primarily oxygen and carbon dioxide, from water. This process is essential in preventing corrosion and scaling in steam boilers and other equipment. Deaerators can be found in various industries, including power plants, chemical processing, and food production, where water quality is paramount.

Types of Deaerators

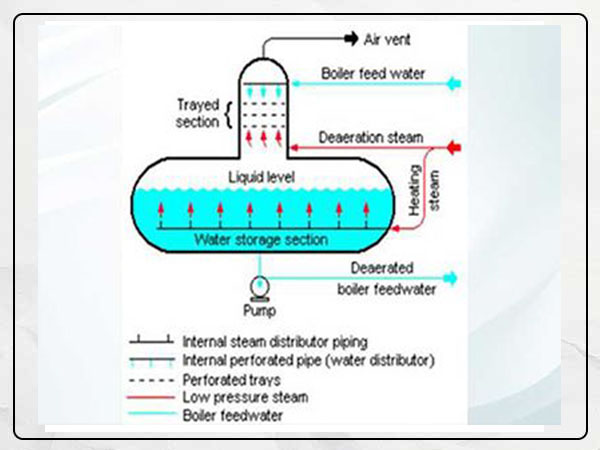

- 1. Tray Type Deaerator: This design uses multiple trays or stages to enhance the removal of dissolved gases. The steam rises through the trays, causing the water to flow down, effectively deaerating it.

- 2. Vacuum Deaerator: Operates under vacuum conditions, which reduces the boiling point of water, aiding in the removal of dissolved gases at lower temperatures.

- 3. Spray Type Deaerator: In this system, water is sprayed into a steam chamber, allowing the steam to strip away the dissolved gases. This type is efficient and compact.

Features of Deaerator Tank :

We are the Deaerator Tank, Deaerator Storage Tank Manufacturers & Suppliers in India, Maharashtra which provide the following features:

| Features | Explanation |

|---|---|

| Removal of Gases and Oxygen | The primary function of deaerators is to effectively remove non-condensable gases and dissolved oxygen from boiler feedwater. |

| Increased Feedwater Temperature | The feedwater gets heated by deaerators to almost its saturation point. As result, less energy is used to heat the water inside the boiler, improving boiler efficiency. |

| Water Supply & Storage | The treated boiler feedwater is kept in pressurized containers called deaerators. |

| Design Variations | There are two main types of deaerator tanks: tray-type and spray-type. Depending on the specific requirements of the application, each offers advantages. |

Benefits of Deaerator Tank :

- Minimizes the rusting of steam boilers

- Increases the steam boiler's efficiency

- Lengthens the steam boiler's lifespan

- Lowers the expense of running steam boilers

- Enhances the steam's quality

- Reduces the effect of steam boilers on the environment

Specifications of Deaerator Tank :

- Capacity: This is the quantity of deaerated water that the tank has the capacity of holding, measured in liters or gallons. It needs to be sized to provide sufficient surge capacity and meet the boiler's feedwater demand.

- Operating Pressure: This means that this is the greatest amount of pressure that the deaerator tank can bear it has to be compatible with the operating pressure of the boiler.

- Design Temperature: This is the greatest temperature the deaerator can tolerate, guaranteeing safe operation under typical circumstances of operation. It is similar to operating pressure.

- Control System: Some deaerators have integrated control systems to regulate water level, temperature, and pressure within the tank, ensuring optimal performance.

Applications of Deaerator Tank

We provides deaerator tank to various industries in India, Maharashtra.

- Power Plants: In order to eliminate oxygen that is dissolved and other gases from boiler feedwater, deaerators are crucial in thermal power plants.

- Chemical Processing: High-purity steam is required for a number of chemical processes. Deaerators make sure that oxygen is eliminated, which may lead to contamination of products and affect some chemical reactions.

- Oil and Gas Industry: Steam-based operations in petrochemical and oil refineries require deaerators. Eliminating oxygen can aid equipment and pipes that transport hot fluids from corroding.

- Food and Beverage Production: To avoid oxidation and guarantee product quality, deaerated water is necessary for food and beverage processing. Applications for deaerators include brewing, sterilizing, and drying processes.

- District Heating Systems: Large-scale heating districts depend on deaerators to protect the pipelines and boilers that provide hot water to buildings and other buildings.

- Marine Applications: To protect boilers used for power or other onboard operations, ships and other marine vessels frequently use deaerators.

We are leading Deaerator tanks Manufacturers, Suppliers, Exporters in India. Deaerator tanks remove dissolved oxygen and gases from boiler feedwater, preventing corrosion in boilers and extending equipment life. They also preheat water for improved boiler efficiency and act as pressurized storage for deaerated water. Available in tray-type and spray-type designs, they come in compact options for space-constrained facilities. Advanced models offer automation and monitoring for optimal operation. Contact Thermin Energy System Pvt. Ltd. we provide 24/7 customer service.

FAQ’s

A: Higher efficiency (lower residual oxygen) reduces corrosion risk, leading to longer equipment life and lower maintenance costs.

A: They are vented out of the deaerator system through a dedicated vent line.

A: The deaerator is typically located between the deaerator heater and the boiler economizer. Deaerated water is then fed into the boiler for steam generation.

A: For safe and reliable deaerator tank operation, ensure proper pressure relief valves and perform regular inspections and maintenance.

A: Deaerator tank technology advancements focus on efficiency (lower pressure drops), automation (advanced control systems), and sustainability (exploration of eco-friendly materials).