Pressure Reducing And Desuperheating PRDS Station Manufacturers India, Maharashtra

Welcome to the Thermin Energy System Pvt. Ltd., We are leading Pressure Reducing And Desuperheating Stations Manufacturers in India. Suppliers, Exporters of PRDS Station in India, Maharashtra. PRDS are necessary to manage steam conditions in industrial facilities. These devices operate as two tools in one a pressure control valve lowers the pressure of high-pressure steam, and a desuperheater that sprays water into the steam lowers the temperature. This perfect control means that steam is delivered to downstream equipment at the right pressure and temperature for the best efficiency.

Why Use Pressure Reducing Desuperheating Stations

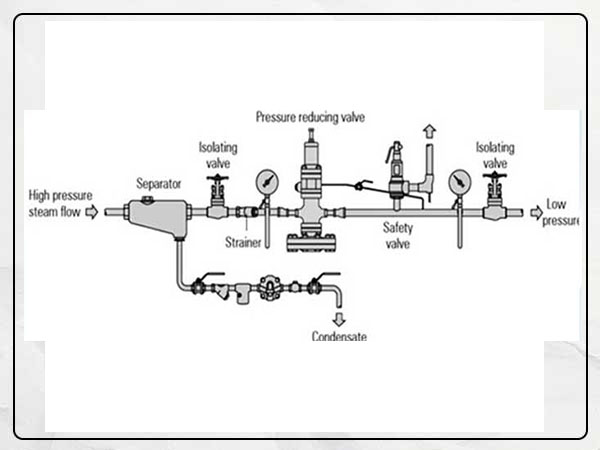

Lowering of Pressure Industrial steam systems requires Pressure Reducing Desuperheating Stations (PRDS) to enhance processes and protect equipment. PRDSs shield equipment unsuited to handle high-pressure steam from damage by lowering the boiler's capacity to produce steam at both a lower temperature and pressure. In addition, they ensure that different downstream applications receive steam at the exact temperature needed for proper operation, leading to efficient steam use and improved overall process management.

Functions of Pressure Reducing Desuperheating Stations:

Pressure Reducing And Desuperheating PRDS Station Manufacturers India, Maharashtra. Lowering of Pressure for industrial steam, Desuperheating Stations (PRDS) are comparable to tag-team champions. They take on two obstacles:

- Pressure Reduction: The high boiler pressure is lowered to a level that is safer for equipment downstream by acting first through a pressure control valve.

- Temperature Control: A desuperheater assumes control next. To bring the temperature of the steam down to the precise level needed for a certain activity, it mists water into the steam like a cool mist.

Features of Pressure Reducing Desuperheating Stations (PRDS)

We are Pressure Reducing Desuperheating Stations Manufacturers, Suppliers in India, Maharashtra provide the following features:

- Combined Functionality: PRDS units combine two features into a single unit. A pressure control valve performs the first duty by accurately reducing the high-pressure steam output from a boiler to the appropriate level. By doing this, harm to downstream machinery that might not be built to sustain such high pressures can be avoided.

- Desuperheating Mechanism: The second function involves controlling the steam's temperature by the use of a desuperheater. Boiler steam is often overheated, which means that at a particular pressure, the temperature of the steam is greater than its saturation point. There are processes that this superheated steam may not be suitable for. By mixing the steam flow with finely atomized water droplets, the desuperheater effectively reduces the temperature of the steam to the required setpoint.

- Temperature Control: The loop that controls temperature does exactly the same thing. A temperature sensor informs a controller after detecting the steam temperature downstream. In order to keep the steam temperature at the appropriate setpoint, the controller adjusts a water control valve that regulates the volume of water pumped into the desuperheater.

Benefits of Pressure Reducing Desuperheating Stations:

- Protection of Equipment: High-pressure steam may be a bully, destroying non-suitable equipment. By reducing pressure to a safe level, avoiding expensive fails, and extending the life of equipment, Pressure Reducing Desuperheating Stations become monitors.

- Process Optimization: Not each step has to be the same. For optimal outcomes, some need the steam to be at a specific temperature. By accurately managing the amount of water injected for desuperheating, Pressure Reducing Desuperheating Stations ensure precise temperature control, leading to organized and efficient processes.

- Enhanced Safety: Uncontrolled high-pressure steam can be dangerous. By controlling pressure, Pressure Reducing Desuperheating Stations reduce this risk and make the workplace safer for employees.

- Enhanced Efficiency: Processes can run as effectively as they can provided the temperature is closely monitored. Pressure Reducing Desuperheating Stations ensure the best possible use of precious steam resources and save energy loss by supplying steam at precisely the right temperature.

- Versatility: With a range of desuperheater options, including fixed nozzle, variable nozzle, and Venturi designs, Pressure Reducing Desuperheating Stations may meet a variety of uses. They can be customized for a range of industrial applications due to their adaptability.

Applications of Pressure Reducing Desuperheating Stations:

Pressure Reducing Desuperheating Stations find applications in various industries that rely on steam for processes, including:

- Power generation plants

- Chemical processing plants

- Oil refineries

- Food and beverage processing facilities

- Paper mills

- Textile mills

We are the foremost Pressure Reducing Desuperheating Stations, Manufacturers, suppliers, exporters in India.are essential to ensuring the secure and efficient utilization of steam in a variety of industrial processes. By using a pressure control valve to lower the high boiler pressure to a level suitable for downstream equipment, these systems operate as dual regulators. After that, a desuperheater takes over and uses water spray to reduce the steam's temperature to the exact level needed for every particular application. Pressure Reducing Desuperheating Stations use control loops to continuously monitor and modify temperature and pressure, protecting machinery, simplifying processes, and increasing the general efficacy of the steam system. Contact Thermin Energy System Pvt. Ltd. for free consultation.

FAQ’s

A: For desuperheating, you can choose between fixed nozzle for constant water flow, variable nozzle for precise temperature control, or Venturi for efficient atomization.

• Power generation plants

• Chemical processing plants

• Oil refineries

• Food and beverage processing facilities

• Paper mills

• Textile mills

A: Regular maintenance of Pressure Reducing Desuperheating Stations involves inspecting components, cleaning nozzles, calibrating sensors, and ensuring control system functionality.

A: The price of a Pressure Reducing Desuperheating Stations depends on its size, desuperheater type, materials, and control system complexity.

A: Email us: sales@therminindia.com/ darekar.satish17@gmail.com

Call us : +91 9552570679 / +91 9422090679