Waste Heat Recovery Boiler in Cement Plant

We Serve (WHRB) Waste Heat Recovery Boiler for Cement Plant in India. We are leading Manufacturers of Waste Heat Recovery Boiler in Cement Plant in India. Cement manufacturing is a highly energy-intensive process. Given the fragile and changing nature of today's fuel and power environment, cement mills should use waste heat recovery-based solutions.

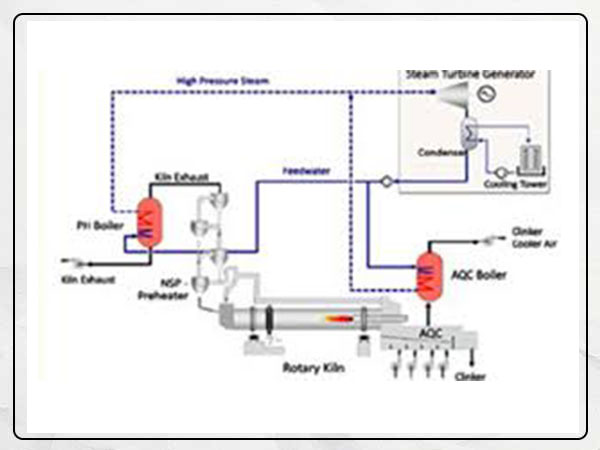

A Waste Heat Recovery (WHR) boiler in a cement plant captures the heat from the exhaust gases of the kiln and the clinker cooler, which are otherwise wasted, and uses it to generate electricity or for other heating applications. This process enhances energy efficiency and reduces the overall carbon footprint of the cement manufacturing process.

A Waste Heat Recovery (WHR) boiler is employed to capture this otherwise wasted thermal energy, converting it into usable power. This innovative technology improves the energy efficiency of the cement manufacturing process, leading to significant reductions in both energy consumption and greenhouse gas emissions. The WHR boiler works by transferring the heat from exhaust gases to a working fluid, typically water, which then generates steam. This steam can be used to drive turbines for electricity generation or for other heating applications within the plant. Implementing a WHR system not only offers economic benefits through energy savings but also contributes to sustainability efforts in the industry.

Applications:

- Greater energy security - helps meet up to 35% of power requirements.

- Increased standing in the market

- Regulatory push: Guidelines mandating the usage of a minimum of 5-10% renewable/WHR energy are already in place in many states.

The cement factory generates waste heat after the suspension pre-heaters downstream of the rotary kilns and clinker coolers.

Product Features:

1) Waste Heat Recovery Boiler for Pre-Heater and Calciner

- Horizontal boiler with vertical tubes for consistent dust removal and gas delivery.

- A proven technique for handling high dust-laden gases of the pre-heater and calciner.

- Inline or staggered heat transfer area.

- Cross-flow gas direction provides effective heat transfer.

- Fully field-tested de-dusting hammering mechanism.

- Higher water hold-up capacity to accommodate any steam variations.

- A proven technique for handling high dust-laden gases of the pre-heater and calciner.

- Better accessibility

2) Waste Heat Recovery Boiler for Clinker Cooler (with or without mid-tap off)

- Vertical boiler with horizontal tubes.

- Cross-flow gas direction ensures effective heat transfer.

- Proven design for extremely abrasive AQC gasses.

- Available in both forced/natural circulation designs unlike other designs.

- Flexible layout with less floor area and improved heat transfer thanks to the special finned design.